Traditionally, cannabis cultivators have had to rely on “mother plants” to produce clones. Cloning from mothers over time can lead to weakened plants, inherited pathogens, and inconsistent harvests. In other words, growers don’t know what quality they’re going to get, which means the consumer can’t predict what they’re going to get either.

It sounds logical to think that if a DIY grower gets their hands on a clone of one of their favorite strains, that they would end up with the same profiles and effects of the strain they started with. It doesn’t work that way though: 10 cultivators might have ten different versions of Skunk or Runtz. Most plants have genetic differences even among strains that are supposed to be identical.

Traditional cannabis clones are cuttings taken from a female plant that is kept in a state of perpetual veg — called a mother plant. She will herself have been either a clone or grown from seed. There’s no limit to how many cuttings of clones can be taken… imagine a room full of infinitely self-reflecting mirrors. Now imagine if that

Creating Healthy Cannabis Plants

Traditional cannabis cloning entails taking a cutting of a mother cannabis plant and rooting it to grow a genetically identical plant. It works in theory, because you get guaranteed female cannabis plants and a shorter time to harvest than growing cannabis from seed. But it can produce problems too: If your mother cannabis plant has a flaw, your clone will have the same flaw. Some cannabis plants don’t take to cloning well. There is a high potential that all of your cannabis plants will be infected with a pathogen if your mother plant is infected. Cannabis clones are sensitive to environmental stresses and the quality can change over time as the cloned cannabis plants are exposed.

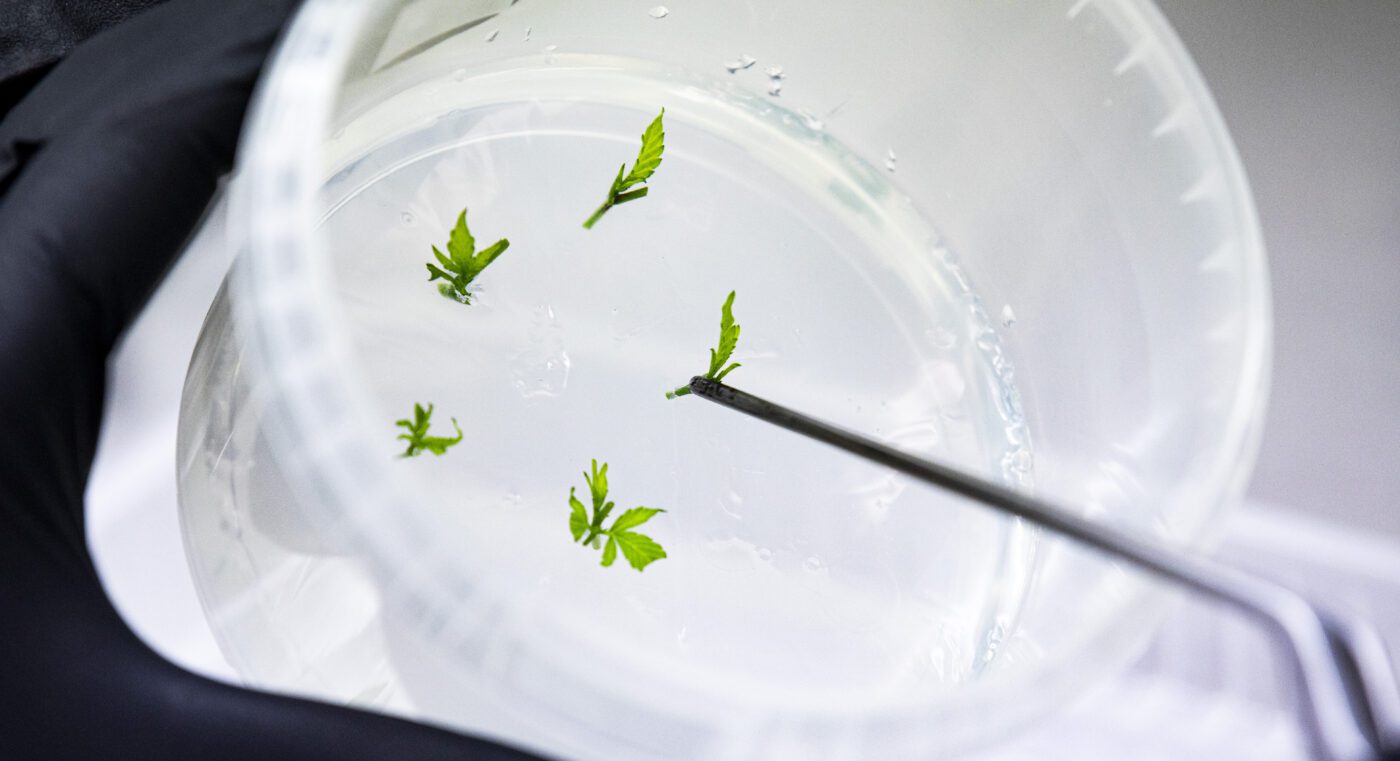

Tissue culture technology provides the ability to quickly produce identical, disease-free cannabis starter plants with customized and consistent characteristics. Cannabis tissue culturing (also known as micropropagation) has been widely used in the agricultural plant industry since the 1950s. Advantages of cannabis tissue culture include the ability to produce many more starter plants than traditional cannabis cloning. MJBiz Daily reports that 100 cannabis clone cuttings per month can yield about 5,500 clones per month, but cannabis tissue culturing can produce millions per year.

Conception Nurseries has the world’s largest commercial operation that offers cannabis clones grown from tissue culture. The company has labs in both Sacramento, California, and Hillsboro, Oregon, and is looking at expanding into other states for cannabis cultivation.

Kevin Brooks is the CEO of Conception Nurseries. Prior to joining Conception, Brooks was CEO of both Cookies Management and Connected Cannabis. To him, healthy cannabis plants were the largest vulnerability and the largest opportunity in the cannabis supply chain. Conception Nurseries is the only company capable of offering commercial-scale cannabis tissue culture to the cannabis industry, revolutionizing cannabis cultivation and cloning.

“With the traditional cutting method of cloning, over time, plants end up losing some of their health, vigor, and some of the original attributes that made that specific plant special,” explains Brooks. “When you tissue culture, you essentially take the core properties, restore them, and that allows you to grow from the reinvigorated gen-zero material.”

If you’re a breeder with some exceptional genetics you want to preserve, tissue culture restoration will leave you with cleaner, healthier genetics. Brooks says the goal at Conception is to take genetics in and restore them to their original health and vigor. “We clean up pathogens in the plants that they picked up over time.”

A grower can easily scale with tissue culture, as well as simply use the techniques to preserve genetics they want to hold on to for future breeding or seasonal production projects.

The start of Conception

“I started my professional career in tech and had a few very successful exits,” Brooks explains. “At one point I decided to get out of tech. I just didn’t enjoy the industry, it never felt comfortable.”

Over lunch one day, he connected with a college friend who had two dispensaries and was looking for investors. “I’ve had a relationship with cannabis for over 20 years — it’s almost a given growing up in California — and I was looking to invest,” says Brooks. “I saw where Colorado had moved to adult use, then Washington and Oregon, and I knew it was just a matter of time for California. I ultimately joined as CEO.”

With Brooks at the helm, the company successfully scaled across the state of California, then rebranded as Connected Cannabis. Scaling requires looking at every aspect of the supply chain, which Brooks did. “We had put out dozens of different pro formas to the team and we missed virtually every one,” Brooks says. “Why did we miss them? It almost always traced back to the mother rooms and underperforming harvests. Well, why did we underperform? The clones weren’t healthy, we started off with bad cuts. But why did we start with bad cuts? Well, because we went back to the mothers and we hadn’t replenished them in the right cycle at the right time. So, the mother plants were sad and we would get hit with pests. Any time we asked why the plants weren’t performing, it nearly always came back to the mother room.”

Since the field of tissue culture cloning was well-developed in other agricultural fields (rice, wheat, corn, and sorghum, among others), they examined how it could be applied to cannabis cultivation. He says it became clear that micropropagation was the answer. “It solved our issues around consistency, pests, and disease,” he says.

In 2018, Brooks left Connected Cannabis to launch Conception with its first facility in Oregon, with California coming online in 2020. “Between the two facilities, we have the capacity of doing north of half a million plants a month, which makes us the largest cannabis tissue culture lab in the world,” he says.

Today, Conception is the exclusive micropropagation lab providing gen zero tissue culture clones to Cookies-approved cultivators in California and Oregon; they are also now authorized to sell a select list of Cookies’ tissue culture clones to licensed cultivators in California and Oregon, including Berry Pie, Gellati, Honey Bun, Londonchello, Medellin 87, Ocean Beach, Pancakes, and Sweet Tea.

Conception’s plantlets are very small plants, yes — 15 viable clones can grow in one container — but imagine millions of very small plants. Their setup allows the output of 6+ million clones a year in a space that would take a traditional cultivator about 10 acres to produce. Plants are rooted and hardened in special grow chambers, and customers receive 48 2- to 3-inch clones in every hermetically sealed plant pack.

Brooks says he modeled Conception to offer what was lacking in other companies, namely, very informed customer service, with someone actually answering the phone and providing help from real experts. “Our value is that we have plant scientists up and down our org chart,” says Brooks. “We put a lot of emphasis on customer success and customer onboarding. We take a lot of pride in answering our phones and making sure that we’re there for our customers, not just when they’re placing orders, but if they have questions or problems down the line. We have managers who regularly visit our clients’ cultivation sites and make sure that they are poised for success.”

Brooks says that as far as he knows, Conception is the only cannabis group worldwide that guarantees their plants are pest- and pathogen-free. Aside from keeping their products at an affordable price point, Brooks says he is proud that the company delivers sterile, hermetically sealed packs right from their facility of gen-zero tissue culture plants.

The company recently launched gen-zero teen plants, which are plants 10 to 16 inches in height. These provide the quickest turnaround time for harvesting as they can save about three weeks of veg growth time. Conception also offers cold storage for interesting genetics that growers want to preserve. Cold storage provides benefits to ensure peace of mind for your genetics, for instance, if you can’t find insurance for your farm. It can help you keep your highest-performing genetics safe for use in the future. “We can clean up the genetics and store them in cold storage for use down the road,” he says.

Brooks says the way they see the market going, given the many different viroids that have been identified, growers will get the most consistent harvests over a timeframe of years with tissue culture. And, not to mention, the ability to keep up with the pace of demand.

“Tissue culture is a critical factor in operational risk mitigation, and will help companies scale,” says Brooks. “As an industry, we need to get more efficient.”

As plant science continues to mature, the company plans to leverage that by offering plants with very specific agronomic traits, whether that’s larger yield, very targeted cannabinoid percentages, or drought-tolerance.

“The way you get there is through clean, healthy tissue cultured plants,” says Brooks. “Tissue culture is so common in agriculture in other foods that you eat every day, but it gets vague for people when you talk about it in terms of cannabis. We really want to explain it and demystify it. Growers are a very curious community and the minute that they learn more, they have the strongest chance possible to make sure that their yields are high and they don’t lose their crop.”