Jack Naito, president of Luna Technologies, lives in Portland, Oregon, where Luna is based. The company designs, manufactures, services, and supports specific types of extraction equipment since 2016. They’ve been building BHO extraction equipment, but earlier this year launched their first ethanol extractor. Pretty much any cannabis product that’s not flower goes through some sort of extraction method, which are primarily solvent-based. Some are non-solvent extracted, but Naito says that percentage is very small, likely 2% to 3%, because non-solvent extraction is less efficient and more expensive.

Not Created Equal

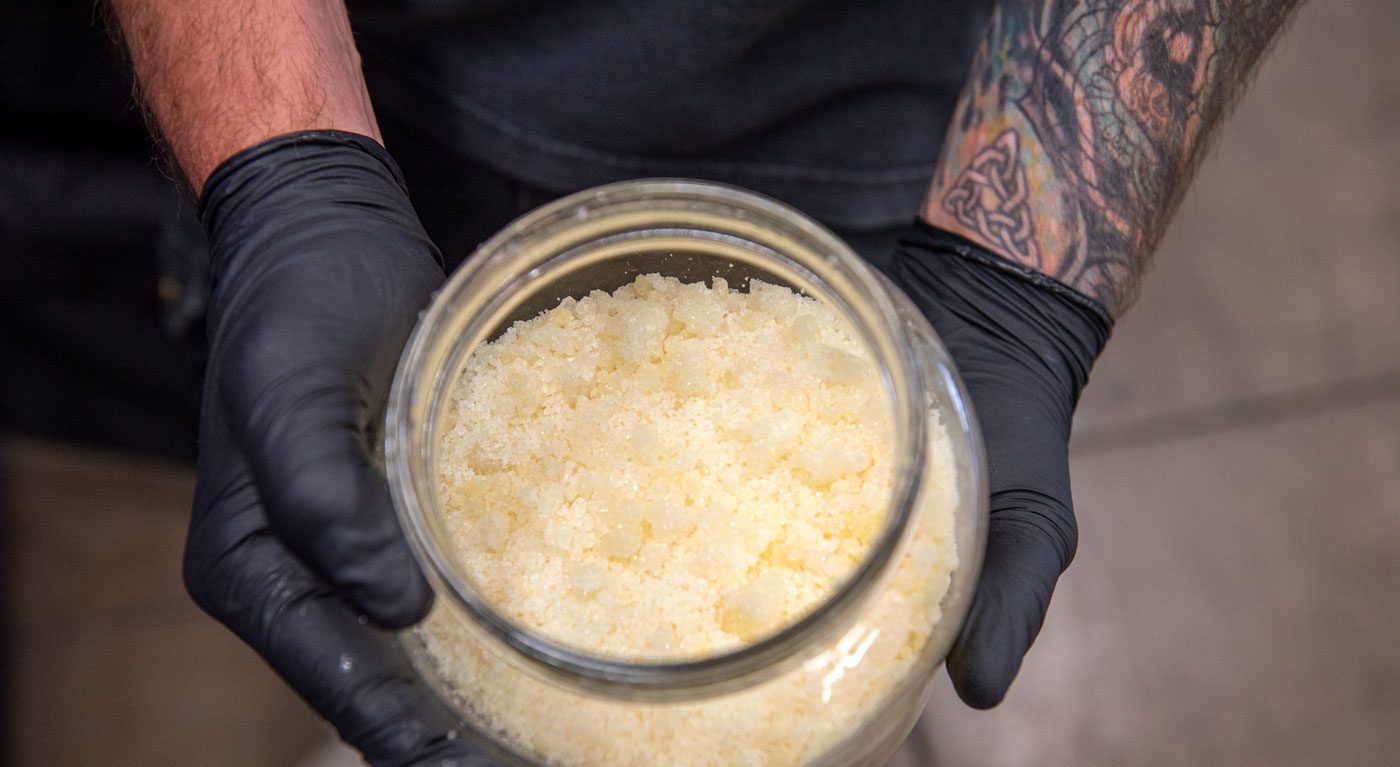

Solventless rosin is made through heat and pressure. Rosin is made using ice water to knock off and collect the resin heads. But most other products — shatter, budder and badder, honeycomb, diamonds, sugar, sauce — are made using solvents.

Solvent-based extracts typically use a volatile chemical, like butane, ethanol, or carbon dioxide (CO2), essential in cannabis extraction technology, to dissolve the trichomes from the rest of the cannabis plant material. This produces potent cannabis oil in automated cannabis processing systems. Then, the solvent must be removed. Extracts are solvent-based concentrate products. And concentrates can be made with either solvent-based or solventless techniques. In other words, extracts are concentrates but not all concentrates are extracts. BHO is an extract created by a solvent technique using butane extraction. Butane has a low boiling point, which makes it easy to extract using lower temperatures with an automated extraction system. But this same quality also makes it dangerous as it is highly flammable and can easily explode.

Back in 2012, Naito was working in R&D at Boeing. A friend since first-grade, Kyler, was working at a dispensary and exploring extracts. “He loved extracts and learned how to make them and then started an extraction business around 2014,” says Naito. “At that time, the industry was mainly a bunch of people in their garages who wanted to make hash oil.” The entrepreneurial extractors put their own equipment together from random parts. It worked, but it wasn’t cannabis specific. Naito says for many people trying to do similar things, the parts were pulled from other industries, such as brewing. It wasn’t very safe, and Kyler was not able to scale up because of it. Naito and his friend came up with a plan, and he quit his job at Boeing.

“At first, we just used his equipment to learn, then we started redesigning his equipment, and then we automated it,” says Naito. “We were surprised that other people hadn’t started automating yet. So we’ve been doing that ever since. What drives us is that Kyler wants to make good products, so then together we design equipment to make that product.”

Now, Luna has equipment in 18 states and four Canadian provinces. The first extractor they launched was called the IO Extractor. A larger version called the Oberon followed. The first production unit of the Oberon is running at Emerald Valley Processors in Eugene, Oregon, owned and operated by Josh Lippold.

Extraction Safety

Black market extractors are the source of most extraction injuries, although some injuries are reported in licensed cannabis processing facilities. Some employers operate without the necessary safety systems in place, which puts product, personnel, and the automated extraction system at risk. An explosion or fire in a lab, especially one lacking other safety measures like adequate exits or fire suppression, can result in life-threatening, or at the very least, life-changing injuries.

The best industry practices to avoid that kind of scenario are to ensure that the existing safety codes are followed. Naito mentions that these codes were not initially written to address the unique dangers of cannabis extraction technology. It wasn’t until 2021 that the National Fire Protection Association added a chapter on cannabis—NFPA 420, Standard on Fire Protection of Cannabis Growing and Processing Facilities. This standard is still in its infancy. Naito was on the UL committee to write code for cannabis extraction equipment, UL 1389, which was released in 2019 and also still needs development.

Automating extraction equipment makes it much safer for the operator and anyone else in the facility. Luna’s completely automated BHO equipment is an industry first. “With manually operated equipment, you have people who are in the C1D1 space working with the equipment,” says Naito. “Once you add automation, the equipment is running and you just have someone going into the hazardous area but all they do is load and unload biomass, which takes about two minutes, and then they walk out. They run the whole thing from the computer screen outside the hazardous area. So putting a barrier between whatever the hazard is and the people working there just makes sense.”

Other industries are automated, so this is just another example of how cannabis is not able to operate on a level playing field like other industries are (yet). As Naito says, it’s not trivial to automate BHO hydrocarbons or butane and propane specifically, because they are more temperamental gasses compared to CO2 or ethanol. “So it is a little bit more difficult,” Naito says. “And companies have tried, but oftentimes there was an engineer on one side and a cannabis expert on the other side and their expertise wasn’t merged.” In other words, it’s difficult to design a machine that results in a quality end-product when the engineers don’t really understand cannabis.

Less Labor, Better Results

Wearing a black shirt and apron, Josh Lippold is working through extracting several batches of material for different clients using advanced cannabis extraction technology. He’s had the Oberon, an automated extraction system, for nearly a year. Emerald Valley has a dispensary, a couple of grows, a processing facility, and a wholesale license with a focus on cannabis processing, making cartridges, and products made with automation. “Having to train people to run a manual hydrocarbon system is dangerous and very complex if you don’t understand what’s happening,” Lippold says. “With automation, you set it up and it does everything automatically, so nobody’s making decisions. We automate every process in-house that we can.”

Emerald Valley always keeps scaling in mind, so they upgraded their chillers right away, with the plan in place to upgrade to the Oberon system. They run the new Oberon five days a week, with a staggered 4 to 10 work week where three technicians work a Monday through Thursday morning shift and three people work a Tuesday through Friday swing shift. This gives everyone a three-day weekend and allows for the equipment to run longer than a standard five-day work week would.

The different types of extracts largely have to do with managing how fast the solvent evaporates. The slower you evaporate, the bigger the THC crystals will grow, forming the type of concentrate known as diamonds, for instance. These are crystals of THCA that are actually made from another type of concentrate called sauce. Sauce, which is glossy and runny, is created by adding solvent to cannabis, and then removing the solvent. Then the sauce is itself heated and pressurized to create the crystals known as diamonds. Shatter can be snappy and hard or more like hard taffy. Shatter with higher levels of THCA is more brittle. Wax is made by whipping air into concentrates. Budder and badder are made by whipping even more. Decarboxylation converts THCA to Delta 9-THC, which doesn’t crystallize. That can be put into cartridges which will never clog. Because Emerald Valley handles the plant material at all stages, they can custom mix their extracts for desired effects, smell, and flavors.

One thing that allows Emerald Valley Processors to be sure that their product is of the highest quality is that they have analytical equipment such as HPLC and GC. “We can take an extract and get an analytical report that will tell us the potency, and if there is any more solvent left in the extract. We can get an answer in 20 or 30 minutes whereas other facilities are sending tests to a third-party lab and waiting a week for results. We can adjust our process and have a run that might take a little bit longer, but we’re going to get more extract out of it.”

Managing Change

As a vertically integrated company specializing in cannabis extraction technology, Emerald Valley has the ability to buy untrimmed flowers, trim it themselves, then resell it or turn the trim into extracts using their automated extraction system. Flower is a tough market now, as people get more excited about other types of products, but the many ways that Lippold and the crew can handle plant materials means that pretty much everything they get can be used.

“We don’t throw anything away,” Lippold says. “We can take other peoples ‘waste streams’ and use basic chemistry to reprocess and create new product SKUs from a normally unusable product most people would consider waste.”

Lippold originally started in this industry as an operations/production manager at the same facility he is currently in. The lab was a complete ground-up build for a CBD company, and Lippold was tasked with managing the facility build-out, working with contractors and engineers to ensure the facility was built to spec in a timely manner. The CBD company was drastically impacted by the pandemic and filed bankruptcy. Then, Lippold and the property owner partnered together and switched the facility over to the recreational cannabis market. The biggest benefit, Lippold says, is that they already had the facility built for cannabis processing and were able to adjust very quickly.

It takes a truly capable person to process, prep a sample, do the testing, get a result, read the result, and understand that result. That ability helps Emerald Valley know that they aren’t going to fail a test, even before they send anything out for the final compliance testing. They can feel good about the product they are creating and their customers can feel good about what they’re buying.

“Having potency and solvent levels and terpene levels is extremely helpful for what we do and for dialing in our processes, and the automation makes everything faster, easier, and safer,” says Lippold. “We owe a lot to the analytical equipment and the amazing team we have running our equipment and processes.”