Like many facets of the modern cannabis industry, most post-harvest processes in use today were adopted from the days of the black market. Yet, the common practice of using HVAC equipment to dry and cure cannabis lacks precision control to properly dry and cure large commercial harvests consisting of several cultivars.

You could grow the highest-quality flowers on earth, but it won’t make a huge difference if you don’t properly dry and cure your harvest. Since all cannabis is judged by people’s smell, sight, and taste, producers must carefully balance chemical processes during the post-harvest phase. By paying careful attention to critical metrics like moisture content, growers bring out the very best in their flowers.

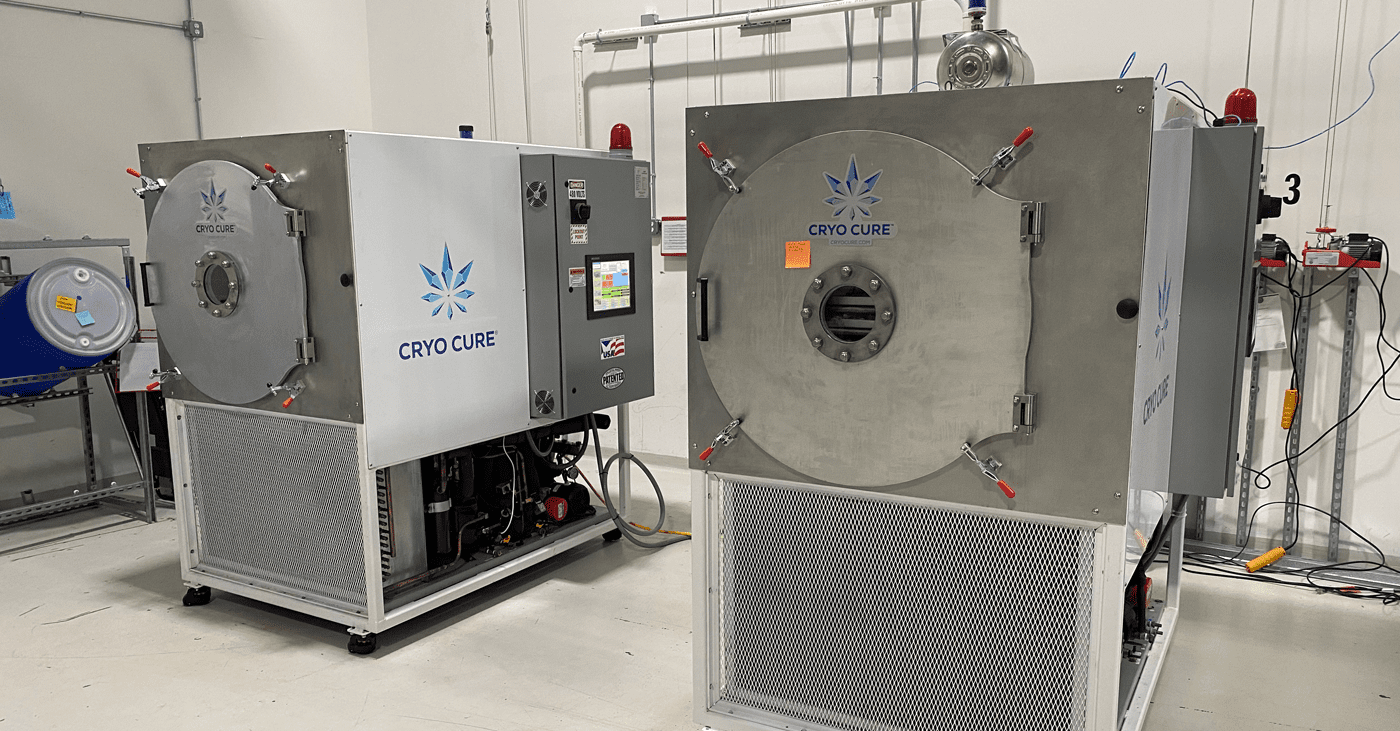

To help bring post-harvest processes to the modern era, equipment manufacturers are developing new methods like freeze-drying and cool curing for commercial production. By engineering comprehensive systems specifically for drying and curing cannabis, companies like Cyro Cure and Cannatrol have given commercial growers unparalleled control over post-harvest processes.

Freeze Drying & Curing with Cryo Cure

Cryo Cure is one of the leading companies offering freeze-drying technology for cannabis. As their co-founder and CEO Tracee McAfee explains, Cryo Cure was “originally inspired by the founders having a need to smoke the freshest and most beautiful flowers directly after harvest.”

While the people at Cryo Cure aren’t the only ones to consider freeze-drying cannabis, they are some of the first to get it right. In early attempts at freeze drying, McAfee tells us, “the flower turned out too fragile, brittle, and flavorless.” Traditional freeze dryers bring the moisture content down to zero, but bringing the moisture this low in cannabis does irreparable damage to terpenes, cannabinoids, and flower structure. In response, the Cryo Cure team figured out the perfect combination of time, temperature, and pressure to pinpoint the ideal water activity for the process.

The Difference

The most dramatic benefit of freeze-drying with Cryo Cure and over post-harvest processes is time savings. In general, old-school line drying and curing methods inherited from the black market occur in several phases that take weeks to accomplish. Quite differently, “Our flower completes drying and curing in as little as 11 to 14 hours, depending on the strain,” McAfee explains.

Since Cryo Cure machines are engineered specifically for cannabis, they offer precision control over moisture content that traditional HVAC systems simply lack. Because Cryo Cure Machines operate on a much shorter timeframe than traditional hanging rooms, they reduce opportunities for errors and equipment failures along the way. The standout feature of flowers processed with Cryo Cure machines is the fact that there is no shrinkage, as buds remain the same size as they were when harvested. Even more, as the Cryo Cure inventors hoped, the fresh smell of these flowers is enough to get anyone’s attention. In a fashion reminiscent of today’s wildly popular live resin products, they dubbed buds cured through their machines as “Live Cured Flower.”

Drying & Curing with Cannatrol

Through a process known as cool curing, Cannatrol has developed post-harvest technology inspired by food manufacturing. As founder David Sandelman explains, Cannatrol uses “the power of vapor pressure to gently dry, cure, and hold your harvest at the perfect water activity level.” Sandelman originally developed this technology for use in cheese aging rooms. Using a patented technology called “Vaportrol,” Cannatrol Systems work as integrated systems that dry and cure cannabis in a single phase as opposed to the drawn-out, labor-intensive processes we are accustomed to. The key to this technology, Sandelman explains, “is the independent control of both temperature and dew point” as well as the ability to adjust the vapor pressure to tweak the environment along the way.

The Difference

Traditional drying methods rely on a patchwork of climate control technologies, as well as a little bit of luck, to get the job done. As Sandleman explains: “With traditional HVAC systems, water is being constantly removed from the flower without much regard to actual moisture content.” When the harvest “feels right,” it is then manually moved to the curing phase, with few of these decisions actually being guided by real data or hard science.

When it comes to curing, growers have traditionally relied on the practice of burping to rid flowers of excess moisture. Yet, not only is burping another practice based largely on guesswork, but cannabis flowers cure at varying rates in different climates, such as dry versus humid regions. Cannatrol Systems for commercial growers can be designed to handle any size harvest over a period of eight to 10 days depending on the strain in question. Even more, these wholly integrated systems are designed to offer a balanced drying and curing environment, regardless of the outdoor climate.

By steadily bringing down water activity to the perfect level between 0.6 and 0.65, Cannatrol technology allows flowers to perfectly express their terpenes and cannabinoids, while also maintaining their structural integrity. This water weight is also critical when it comes to discerning the wholesale value of a harvest. After flowers are brought to the right moisture content, Sandelman explains, “the flower maintains that level until it’s time to smoke.” Importantly, buds cured with Cannatrol can be stored for months in their machines without the degradation of terpenes or cannabinoids, or the proliferation of pathogens.

Here To Stay?

The benefits of working with a new post-harvest technology like Cryo Cure or Cannatrol are tough to ignore. Since cannabis is sold by weight, incremental shifts in water activity can have an incredible impact on profit margins. Not to mention, both technologies greatly reduce the human labor needed to harvest cannabis, while also cutting down on the square footage required for traditional drying rooms.

Operational jargon aside, product quality is one of the most defining characteristics of any successful cannabis brand. In turn, having maximum control over drying and curing processes is one of the most surefire ways to deliver the best possible products to customers. As the cannabis industry grows more competitive, “the perfect cure” will no longer be a niche pursuit, but rather an essential means for product differentiation.