The SunMed story could be subtitled “How One Man’s Greenhouse Legacy Blossomed into a 100-Million-Dollar Cannabis Powerhouse.” In the heart of Maryland, a 500,000-square-foot campus hums with activity, producing some of the most sought-after cannabis in the country. This is SunMed, one of the largest vertically integrated cannabis operations in the United States, if not the world.

At the helm is Jake Van Wingerden, a man whose family history in controlled agriculture spans generations. Van Wingerden’s paternal grandfather, Aart, emigrated from the Netherlands in the 1940s and started an ornamental nursery plant empire which his 16 children and their children have been a part of for decades now. “My whole legacy, life, has been in controlled agriculture,” Van Wingerden explains. Van Wingerden still produces ornamentals, but SunMed Growers is his state-of-the-art greenhouse cannabis facility in Maryland, now the largest cannabis greenhouse on the Eastern Seaboard.

Following in his father’s footsteps, Van Wingerden initially focused on growing petunias and geraniums. But when Maryland legalized medical cannabis in 2015, he saw an opportunity to apply his horticultural expertise to this burgeoning industry. “When Maryland was debating legalizing medical cannabis back in 2014 and 2015, I followed that because my brother had gotten into the cannabis scene out in Colorado,” he says. “So when the application came out, I believe it was 2015 here in Maryland, I applied for and we were successful in winning a growing license on that first round.”

With the addition of an extraction facility in 2021, SunMed started growing and processing branded SunMed Labs products to supply Maryland’s medical cannabis market. Now, they produce flower, pre-rolls, vapes, concentrates, edibles, branded products with Belushi’s Farm, and Keef THC-infused sodas.

SunMed Growers President Jake Van Wingerden has a clear philosophy on growing: “In controlled agriculture, rather than changing the greenhouse to match the plant, let’s make the greenhouse perfect for that stage of the plant and move the plant into that zone.”

This philosophy has led to an impressive operation. SunMed’s grow facility spans 300,000 square feet, housing over 1,500 mother plants and producing around 4,000 cuttings weekly. The company employs more than 200 people and has invested nearly $100 million in state-of-the-art equipment and facilities.

Brad Moran, the director of operations, oversees a sophisticated growing process that begins with a custom soil mix including coco, perlite, and rice hulls, which helps the plants absorb more silicate, which in turn helps with powdery mildew resistance. Plants move through various zones optimized for different growth stages, all monitored and controlled with precision.

Plants sit inside RootMaker air pruning pots inside of a white shell, a color that was chosen to keep the root zone cooler. The pots are reused after being washed and steam-sterilized. The team recaptures and reuses all of their irrigation water that comes off of the plants. “We are storing, treating, and then blending it back in our daily irrigation activities,” he says. “We are very mindful of the Chesapeake Bay, and we want to minimize our impact as growers by minimizing the amount of feed that goes downstream from our facility. We just feel like it’s being good stewards of the land to minimize that impact.”

Post-harvest, the operation continues to impress, with the post-harvest manager guiding the cannabis through a 14-day drying process in carefully controlled rooms set at about 60 degrees and about 58% relative humidity. The buds are sorted by size before going into the cure rooms, since small buds will dry a lot faster. The packaging department can produce up to 12,000 joints a day, using eco-friendly packaging materials including a gray tube that’s made out of rice husk and a white tube that is made out of bamboo.

The processing lab oversees the creation of a wide range of products, from vapes and gummies to chocolates and beverages. The facility processes about 2,000 pounds of biomass weekly, and they’re selling up to 100,000 vapes a month. Executive Chef Matt Fusello, formerly a bakery owner, brings culinary expertise to the edibles production. “One of the coolest things about me being in this facility is our ability to try anything here,” Fusello says. “We like to joke around that it’s like Willy Wonka’s chocolate factory down here. If you want to try to make it, go ahead and make it.”

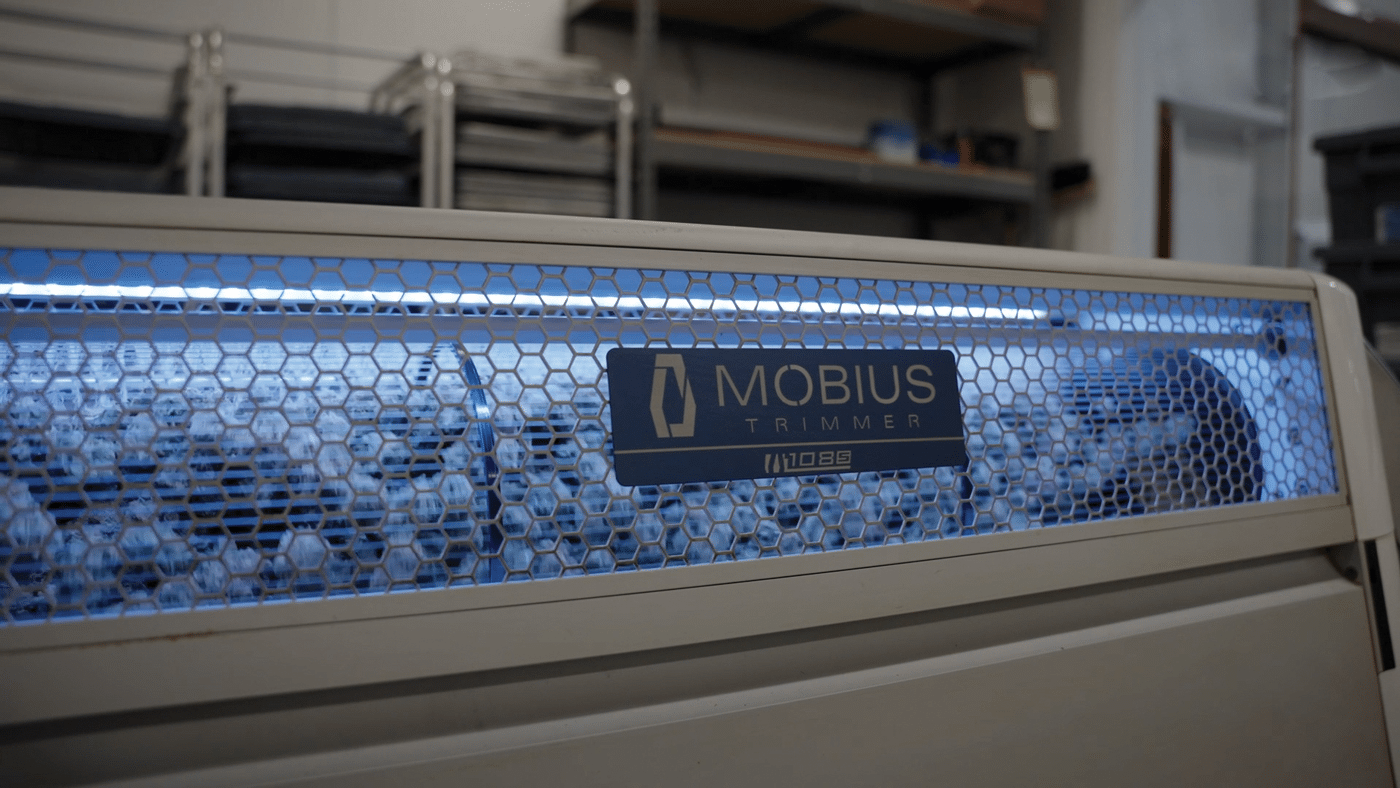

But SunMed’s success isn’t just about volume; it’s about quality and innovation. The company has become a house of brands, partnering with well-known names like Cookies, Belushi Farms, and House of Kush. They’ve also invested heavily in research and development, constantly refining their processes and products. All of the extraction and processing equipment is state-of-the-art and costs “north of $16 million,” according to Van Wingerden. It’s clear that SunMed doesn’t cut corners when it comes to making investments. That commitment to investing in quality extends to SunMed’s employees too.

Van Wingerden’s approach to business is as impressive as his growing techniques. When recreational use was legalized in Maryland, he gave every employee a $10,000 raise, demonstrating his commitment to his team. “The facility is a big, giant tool,” he says, “and a tool is only as good as the person using the tool. The hammer and the saw can’t make a beautiful desk, right? You need a carpenter to do that. And so this tool that I’ve given to my team makes my team successful, and the team, to me, is the most important thing.”

Justin Garcia is the compliance and public relations manager at SunMed Growers. When he heard that CannaCribs was going to feature SunMed, he knew that part of the focus was going to be on the facility’s size — and while it is certainly impressive, that’s far from the whole story. Keeping in mind their legacy as a plant company keeps them focused and balanced.

“We look at our story as a company, our founder’s story, and our history of being a plant company, and we look at the plant the same way,” Garcia says. “We tried to see the efficiencies in the grow and the way that we can grow at scale in traditional horticulture worlds and then bring cannabis into the fold of that kind of modern, innovative, and automated style of growing.” he says.

The company has invested a lot into automation and into making the facility efficient, to be able to continue to grow as a company and to be able to ride the wave of whatever changes might come in the industry.

The other thing that Garcis says really differentiates SunMed is just how flexible and versatile their kitchen area is. “We built this 25,000-square-foot standalone processing lab with dedicated confectionary spaces because we know we want to make gummies. We know we want to make chocolates.”

And this was before they were approached at the end of last year to consider doing a beverage. Now, they have Keef, which comes in flavors like root beer, cola, orange “kush,” grape, and blue raspberry, each with 10 milligrams of THC. Garcia is looking ahead to the next thing. “The sky’s the limit as far as what you can infuse,” Garcia says. “So I was always very excited to see, like with our scale and with the right team that we have, what kind of products we were going to be able to turn out from our kitchen.”

At the time that I spoke with Garcia in mid-summer, SunMed was going through their cGMP audit, which is shorthand for Current Good Manufacturing Practices. “What that’s going to mean for us, specifically in the Maryland market, is the ability to produce higher dose edibles, but on the more holistic range, cGMP is just a way of saying that not only do we make all these products, we make them very well and in accordance with modern, clean, hygienic, up-to-date standards of any modern food-based or any type of manufacturing.”

With so much emphasis on scale, I asked Garcia if he felt that a grower loses any sort of craft connection to cannabis when it’s grown the way that they are at SunMed. “Great question,” he conceded. While most cannabis growers avoid comparisons to the alcohol industry, Garcia noted that there are some similarities. “There’s a lot of room for craft breweries. There’s a lot of rooms for for IPAs and for pilsners and stouts and porters, and there are people dedicated to the craft of making a great beer, and then equally available in those stores that sell those same products are Budweiser, Michelob, and Miller,” he explains. “And those are a lot of people’s favorite drinks.”

There are benefits to having a consistently good product be consistently available, and that’s a hole SunMed can fill. People have started to recognize brands and find familiarity with that, especially as cannabis markets fluctuate. When certain cannabis brands are available in different states, it’s natural for people to develop an attachment to the brands they like. And it’s best case if the products people want to see are actually available wherever the person is shopping.

“So even when this was a medical only market, we believed in an idea of what we call continuity of care,” explains Garcia. “When this was just a medicine and people looking for strains to help their specific ailments, if they found that our Golden Pineapple or Snoop Dogg OG was incredibly effective for them, well, every time they go to their home dispensary, we want to make sure it’s on the shelf,” he says. “We’re constantly dedicated to trying to improve, but we also always want to have a good, consistent, affordable product that people can rely on.”

Garcia went on to stress that SunMed is a single-state operator with no intention of becoming a multinational conglomerate. They aren’t the kind of company that is going to have a “customer complaints number” that’s routed somewhere else in the world. “We are grown in Maryland, made in Maryland,” he says. “And when you call our office and there’s either a compliment or a complaint, you’re talking to somebody on-site at the facility that makes it. This is a family owned company that treats people well and provides a quality, affordable way of life by being in the cannabis industry. And that’s what we feel is our biggest contribution to this industry, and to the state of Maryland in general.”

As the cannabis industry continues to evolve, SunMed stands as a testament to what can be achieved when agricultural expertise meets cutting-edge technology and a commitment to quality. From its roots in traditional horticulture to its current status as a cannabis powerhouse, SunMed is not just growing plants – it’s cultivating the future of the industry.