With regulated adult-use cannabis now a decade old in certain parts of the country, we’re beginning to see producers focus on every facet of the supply chain in the name of profitability.

Growers are finding significant correlations between basic garden inputs and strong business performance. In today’s industry, even something as seemingly innocuous as the density of your cultivation substrate can impact important metrics like labor costs or water consumption.

To succeed, commercial producers must hedge profitability on biological processes deeply embedded in plant genetics. They must also account for a kaleidoscope of other variables associated with growing cannabis in controlled environments, everything from airflow to lighting.

The Business Function of Growers

Whether it be a consumer at a dispensary or a compliance officer with a regulatory agency, the notions of quality and consistency are paramount for commercial growers. These factors can make or break a cannabis business in a short time. Growers are thus tasked with the daunting task of reducing risk in crop production – a notion that would make any farmer nervous.

While horticulture and plant science play important roles, the main responsibility of today’s commercial growers is to manage as many variables as possible. Regardless of the growing environment, consumers and compliance officers demand clean flower with consistent THC levels – while investors demand a sizable profit.

Understanding Risk Control in Commercial Cultivation

Although biological organisms like cannabis plants can be unpredictable, growers focus on key inputs to guide crops as effectively as possible. While these inputs may vary slightly depending on your cultivation environment, a few key considerations remain essential:

- Substrates

- Water

- Nutrients

- Airflow

- Lighting

Inconsistent management of these variables prevents cannabis crops from reaching their full genetic potential. This leads to a ripple effect, making it difficult for growers and business owners to predict harvest sizes and meet business targets and financial projections.

How Consistency of Inputs Impacts Profitability

An imbalance in inputs like water, nutrients, or cultivation substrates can wreak havoc on production capacity and overall yield. Here’s how:

Substrates

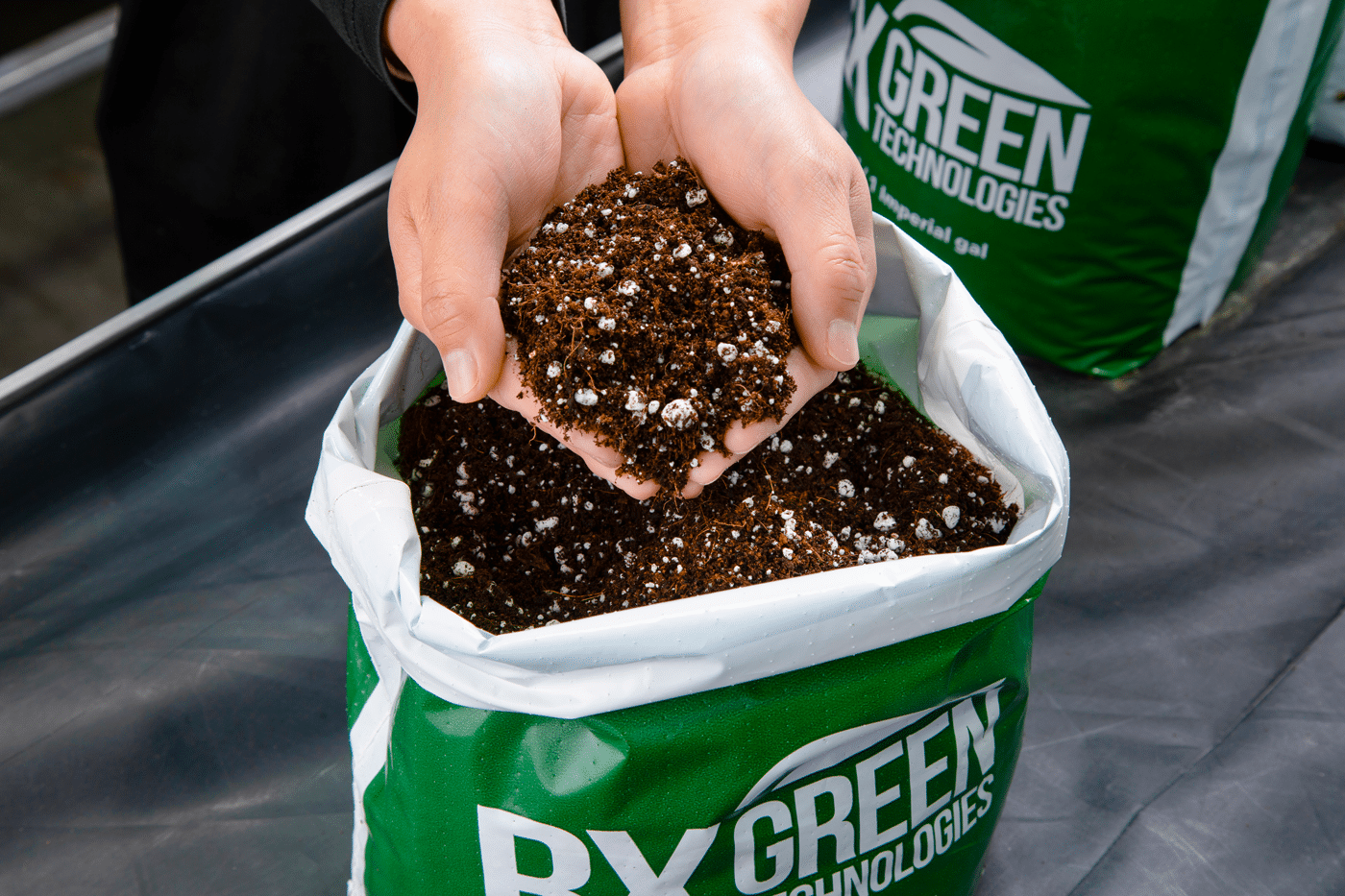

Poorly mixed substrates can be detrimental to your garden’s health. If there are clumps in the soil, it will retain water unevenly and cause issues with your roots. If substrates aren’t adequately mixed and nutrients are evenly distributed, it can create hotspots that burn your plants.

Without consistent inputs, it’s next to impossible to troubleshoot your garden. When you use consistent inputs, you can fine-tune your soil and plant nutrition processes as you go. Remember, substrates should look and feel the same with every bag and have consistent pH.

Pest and Disease Resistance

Low-quality inputs can also introduce pests and diseases to your garden. For example, coco coir or soil that hasn’t been tested for pathogens can harbor any number of unwanted guests. If you open a bag of soil or coco and bugs come flying out, think twice about using it.

If you use living substrates like soil or coco, the manufacturer should go to great lengths to remove any harmful pathogens, while allowing beneficial organisms to remain.

Labor

Since every step in the cannabis supply chain is linked, even labor can be impacted by the quality of the inputs you choose.

Tasks like breaking up substrates to ensure consistency, or repeatedly conducting pH tests due to unreliable nutrient solutions, can be time-consuming and labor-intensive. Similarly, low-quality nutrients can also clog fertigation systems, causing issues for facilities teams and growers. In the worst situations, poor-quality water can lead to endless troubleshooting for your cultivation team.

Precision Growing for a Specific Product

Growers are now being asked to produce crops to meet very specific needs. To illustrate, growing flower for a cold press will likely differ significantly from cultivating for pre-rolls.

Clean nutrients and substrates give growers the ability to steer crops as needed. While most nutrients are similar in terms of N-P-K ratios, quality manufacturers stand out with their micronutrients. Dialing in your nutrient regime on a micro level is the key to unlocking precision harvests. The more usable plant matter in your crop, the higher your profit will be at the end of the year.

How Do Commercial Cultivators Reduce Risk with Inputs?

Commercial growers can mitigate the risks associated with garden inputs by partnering with manufacturers that prioritize quality and consistency. As the industry evolves, companies like Colorado-based Rx Green Technologies are rising to meet this demand. Unlike early hydro brands designed for home growers, Rx Green was built for commercial producers, creating coco coir blends and nutrients with an unwavering dedication to quality control and consistency. Companies like Rx Green design products to streamline workflows at commercial facilities, while also offering industry-leading customer support along the way.

Final Thoughts

Cannabis plant science is still in its infancy. Yet the key to unlocking the genetic potential of any strain is providing the right balance of garden inputs. With consistent inputs, you can replicate successful cultivation processes and scale as needed. However, a lack of consistency with garden inputs results in a never-ending battle of troubleshooting and putting out fires.

From reduced labor costs to precision harvests, using quality substrates, nutrients, and water are some of the first steps toward sustained profitability for commercial growers. Consistency is the name of the game in the modern cannabis industry, you’re well advised to control as many variables as possible to find success.